The DG Shipping Process – Part 2: Packaging (Step 3 of 7)

By Terry Poland, Principal Instructor and Consultant

Shipping dangerous goods for the first time? Where to begin and what are the basic steps in the process? Airlines MUST use a checklist, but shippers and others are not required to.

Upon completing a dangerous goods training course, many students go back to their place of business and struggle to get the process started for real – especially first-time shippers. So what do we recommend? The answer is simple: a process. For example, the following process provides shippers with step-by-step guidance to assure all aspects of compliance are addressed in a logical order. While this process is not as detailed as the IATA Acceptance Checklist for air shipments, generally it can be applied to all modes of transport – air, ocean or ground (highway and rail).

- Identification – Proper Shipping Name (with technical name for N.O.S. entries) & UN/Identification Number

- Classification – Hazard Class and/or Division (subsidiary hazards, if any) & Assignment to Packing Group (PG I, II or III, if applicable)

- Packaging – UN Specification, Limited Quantity (LTD QTY), Excepted Quantity (EQ) and/or other exceptions granted by special provisions or packing instructions

- Marking – Proper Shipping Name, UN/Identification Number, From & To Addresses, Quantity (if applicable), other shipment-specific markings as required

- Labeling – Primary & Subsidiary Hazard Labels & Handling Labels (Orientation Arrows, CAO, others as applicable)

- Documentation – Shipping Paper (Dangerous Goods Declaration, Transport Document, Air Waybill, Bill of Lading, etc.)

- Other – Placarding/Special Provisions/State Variations/Operator Variations/Carrier Matters

In Part 1 of this series, we covered Steps 1 & 2, where the shipper Identifies & Classifies the material. Completion of these initial steps will produce the “Basic Description” of the hazardous material including: (1) UN Number, (2) Proper Shipping Name, (3) Hazard Class or Division (and any applicable subsidiary hazards), and (4), if applicable, the Packing Group (PG).

Before proceeding with Step 3 (Packaging), the shipper must have specific details regarding the total quantity of materials being shipped and their prepackaging configuration before proceeding. This would include the total quantity of the shipment, by volume for liquids (expressed in liters) or by mass for solids, gases and articles (expressed in kilograms), and the nature and quantity of the receptacles or other containment methods. Also, note that combination packagings (inner & outer packaging used together) are generally required for passenger aircraft transport and single packagings (drums and jerricans) are usually Cargo Aircraft Only (CAO). (see our Knowledge Base Article on Definitions of Packages). Of course for non-air shipments, both types of packagings are generally acceptable. Finally, most hazardous materials shipments require UN Specification packaging; however, if this is not available, there are two options: (1) Excepted Quantity (EQ) and (2) Limited Quantity (LTD QTY) – please see our Knowledge Base article on these for more information.

Here are a few common examples of the basic description along with the prepackaging configuration and volume of materials:

- UN1090, Acetone, Class 3, PG II, inner 4 x .1 L (100 mL) plastic bottles, non-specification fiberboard outer packaging (see shipping example below)

- UN1760, Corrosive Liquid, N.O.S. (Technical Name), Class 8, PG III, inner 10 X 20 L metal cans, UN 4G fiberboard outer packaging

- UN3480, Lithium Ion Batteries, Class 9, 2 X 4 kg batteries (300 Wh each), UN 4G fiberboard outer packaging

- UN2674, Sodium Fluorosilicate, Div. 6.1, PG III, 2 X 1 kg glass bottles, non-specification fiberboard outer packaging

- UN1114, Benzene, Class 3, PG II, 10 X 220 L steel drums (UN 1A1) single packagings

Once this information is detailed, the mode of transport must be selected based on the shipment priorities. Obviously, this decision can be based on many different considerations, but generally the required delivery deadline date and final destination routing are primary factors. Also, where transportation cost is a significant factor, air transport and packaging costs will generally be much higher than for surface modes. Furthermore, air transport with much higher safety standards, may substantially limit the packaging quantity limits for both inner packagings and the total quantity per package. For extremely large packagings, those in containers of more than 450 L (119 gallons) or 400 kg (880 lbs.), these are not eligible for air transport and must be shipped by surface modes only.

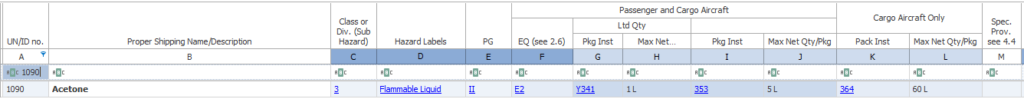

With these considerations addressed, the packing instruction in the modal regulations must be referenced. We will use UN1090, Acetone, as shown in the example above to complete this process for an air shipment. As was discussed in Step 1 & 2, the process begins by consulting the dangerous goods list in the appropriate modal regulations. Below is an excerpt from the IATA Dangerous Goods Regulations, 4.2 DG List:

Essentially, there are four packaging options in the IATA DG list for UN1090 as follows (Note: inner packaging limits are contained in the appropriate packing instruction/reference):

- Non-Specification Packaging, Column F: Excepted Quantity (EQ) – follow instructions in IATA 2.6, which allows for quantities of not more than 30 mL per inner packaging and a total limit of 500 mL per package.

- Non-Specification Packaging, Columns G & H: Limited Quantity (LTD QTY) – follow instructions in IATA Packing Instruction Y341, which allows for inner packagings of not more than .5 L and a total limit of 1 L per package.

- UN Specification Packaging:

- PASSENGER & CARGO AIRCRAFT, Columns I & J: UN Specification Packaging (UN Spec) – follow the instructions of IATA packing instruction 353 which allows for inner packagings of not more than 1 L (glass) or 5 L (metal/plastic) and a total limit of 5 L per package.

- CARGO AIRCRAFT ONLY, Column K & L: UN Specification Packaging, Cargo Aircraft Only (UN Spec CAO) – follow the instructions of IATA packing instruction 364 which allows for inner packagings of not more than 2.5 L (glass), 5 L (plastic) or 10 L (metal) and a total limit of 60 L per package.

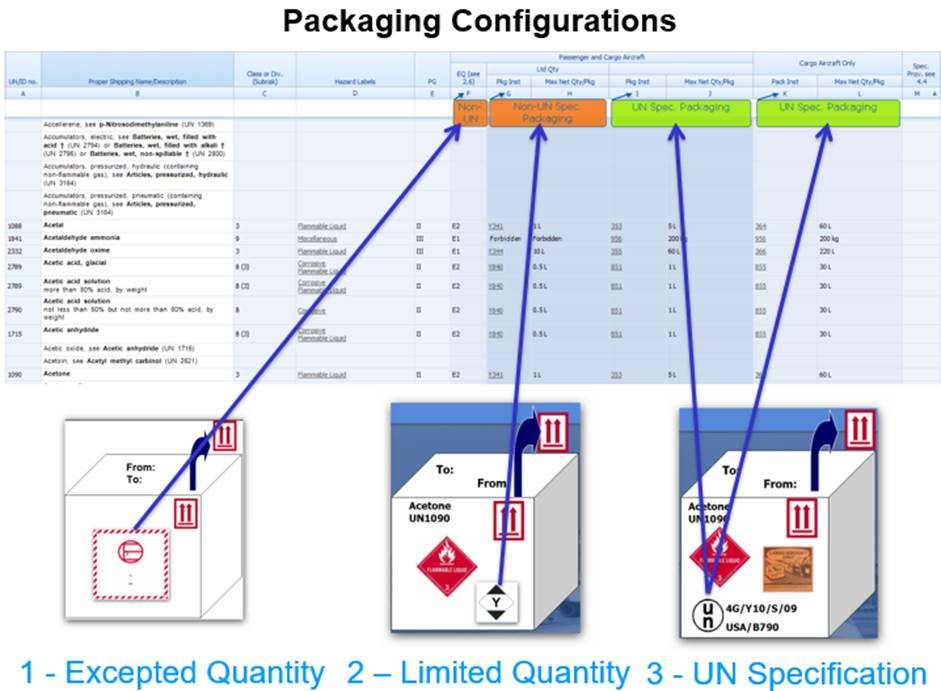

The “Packaging Configurations” are illustrated below for each of the three (3) options described above.

Finally, to complete the packaging selection for a non-specification fiberboard box (which exceeds the inner limit of 30 mL for EQ), the only packing option available would be number 2 above (which allows for inner packagings of not more than .5 L and a total net quantity limit of 1 L per package and a package gross weight limit of 30 kg). Of course, all packages must meet the modal “General Packing Requirements” which typically state that packages must be of good quality and able to stand up to the normal shocks and loadings encountered in transport. The air requirements are, of course, of a higher standard including a 4-foot (1.2 m) drop test, and, for receptacles carrying liquids, a 15 psi (95 kPa) pressure test, sufficient ullage (outage – empty space for expansion) and secondary closures (seals) or plastic liners, to name the most significant of these.

For support requests, please feel free to contact us at support@dgtraining.com

Please watch for Part 3, covering step 4 & 5, “Marking & Labeling” – coming soon!